| Bracing Roll Forming Machine | ||

| Machinable Material : | A) Zinc-plated steel | Thickness(MM): 0.9-2 |

| B) Hot rolled steel | ||

| C) Cold rolled steel | ||

| Yield strength : | 200 - 350 Mpa | |

| Tensil stress : | G200 Mpa-G350 Mpa | |

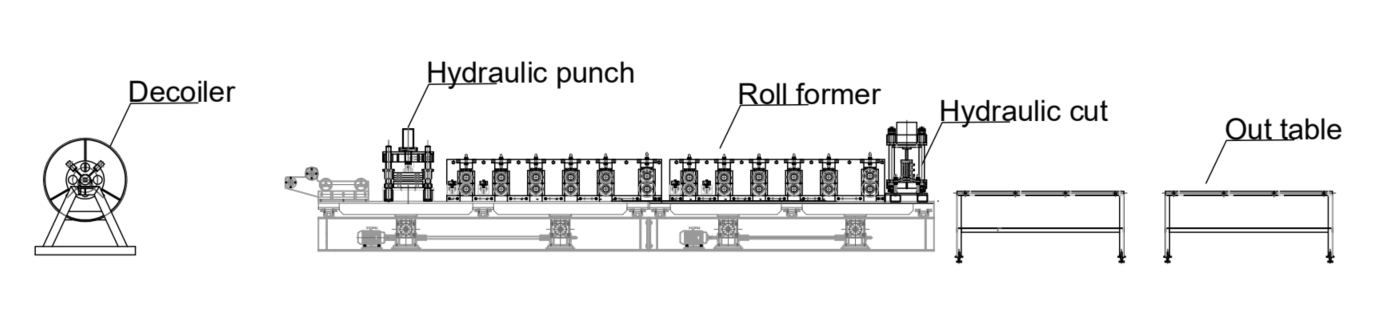

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

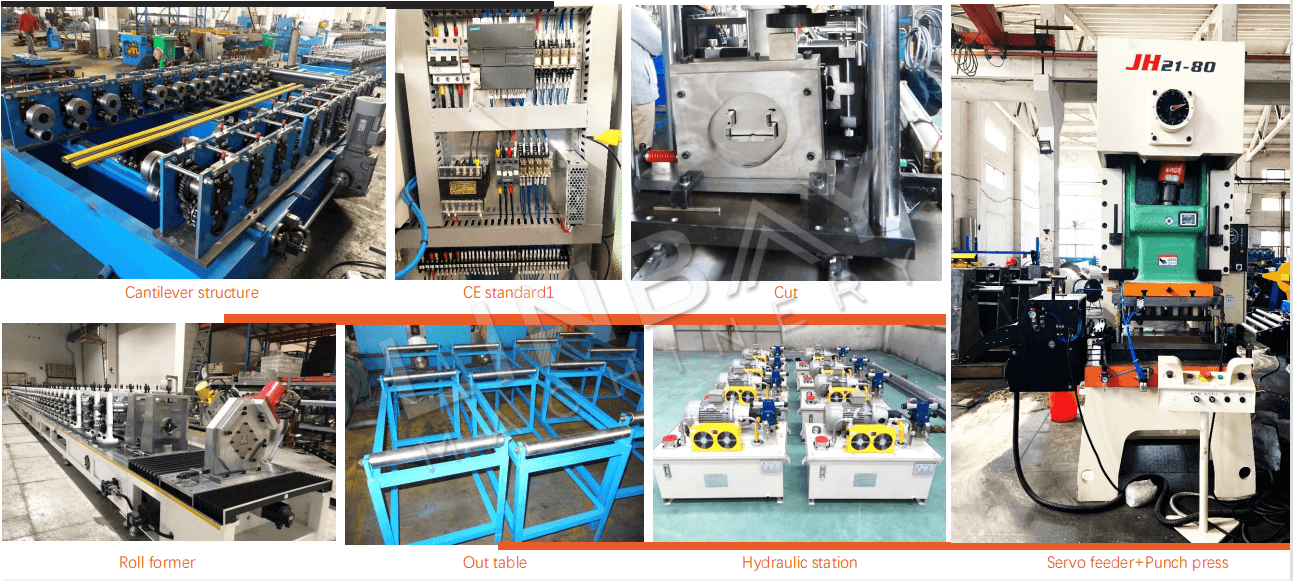

| Punching system : | Hydraulic punch station | |

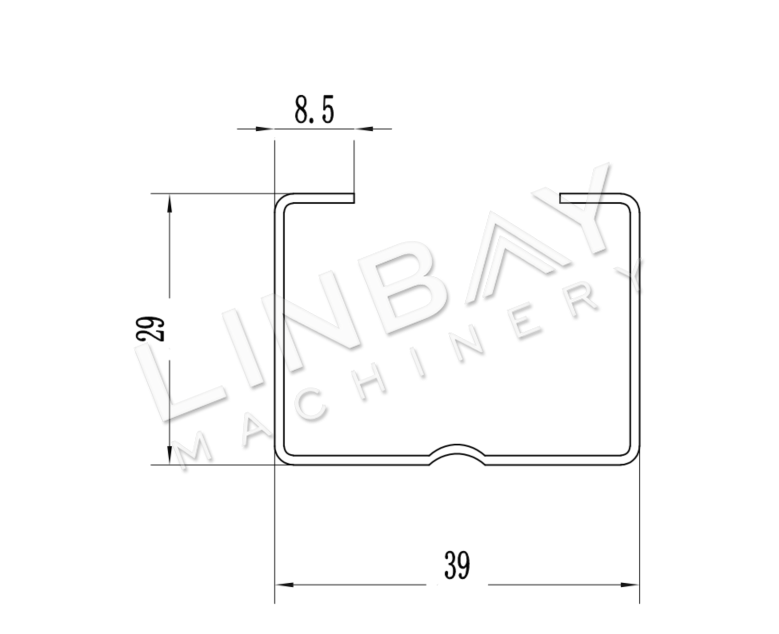

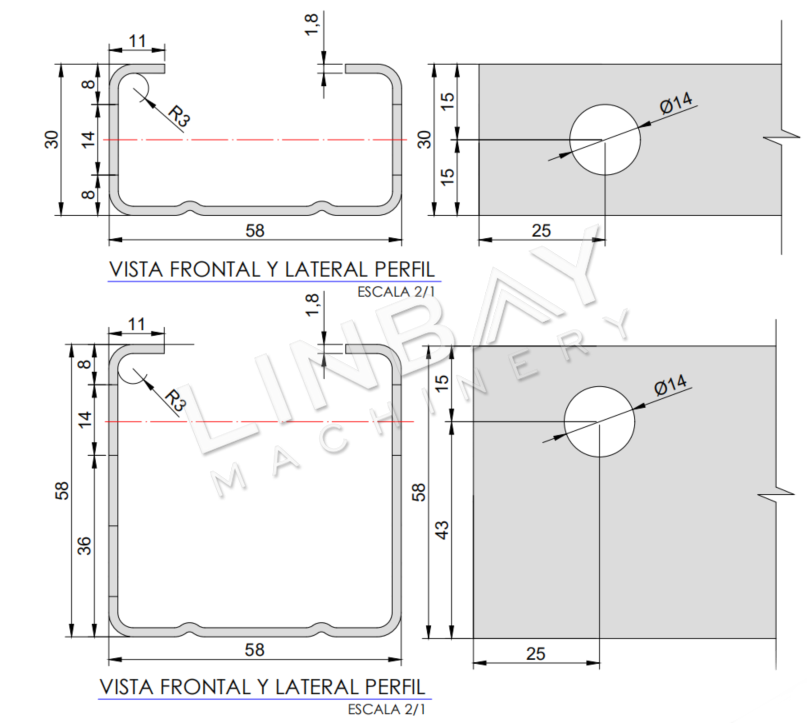

| Forming station : | 14 stands | * According to your profile drawings |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Cast Iron (Optional) |

| Forming speed : | 10-15 (M/MIN) | |

| Rollers’ material : | Steel #45, chromed | * GCr 15 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |